3 Useful Tips To Choose The Right Air Compressor For Your Business

Some things are necessary for easing business operations. One of them getting popular these days is the Air compressors Industrial, which serves the needs of many industries.

Most sectors such as food and beverages, textiles, pharmaceuticals, automobiles, and Agriculture depend on air compressors for a lighter and safer alternative.

There are many things one needs to consider before selecting the right air compressor because different types of air compressors are used for different purposes. So here are 5 useful tips to choose the right one for you.

-

Selecting The Perfect Size

– Consumer Grade: This compressor is meant for regular use by ordinary people. It can be used for inflating tyres at tyre puncture businesses

-Professional Grade: Since they are larger in size, they can power many air tools. The applications include- power water pumps for farms, power gas turbines, sandblasting and food packaging.

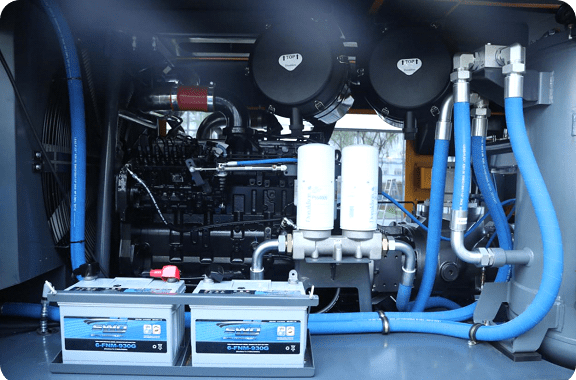

– Industrial Grade: It is the ideal choice for heavy industrial tasks because it can be used continuously and have a strong structure. The applications include: cutting and welding equipment, blow mold gas tanks, drive screws and nuts and many more.

-

Check The Power Requirement Needed For Getting The Job Done

Industrial Air Compressor is available in a range of power outputs. To know which one will work for you, first analyze how much power your job requires and then determine which compressor to buy. The Air compressor industrial’s output is measured in CFM (cubic feet per minute).

-

Check If You Require An Air Dryer

A lot of water is produced by an Industrial air compressor, and although this water can be emptied, the system is not completely dried off. The hardest part of cleaning the Air compressors Industrial is getting rid of the water that is there in the form of vapour and aerosol.

If any of the following issues occur, an air drier is required for air compressors:

- The manufacturer of the compressor indicates that an “Air dryer” is required.

- Pipelines start to rust and corrode

- Your hoses and lines emit liquid water.

- Your air tools exhibit water stains.

- Water vapour is sprayed out of the tool exhaust.

To Conclude

Have a detailed discussion about servicing and maintenance techniques for an air compressor even before you purchase it to avoid dealing with problems later. A compressor’s servicing and maintenance are crucial parts since they reduce labour, costs, and time spent. When equipment is properly serviced and maintained, its lifespan dramatically increases. Air compressors are no exception, therefore make sure all maintenance is performed correctly and on schedule.

Air compressors are expensive; they require substantial investments. In addition, they power a number of crucial tools.

Therefore, it wouldn’t be a good idea to compromise on their output or effectiveness.

Whenever you are planning to buy an Air Compressor Industrial just remind these useful tips or save this blog for future purposes.